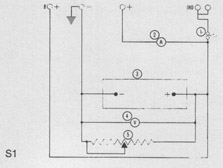

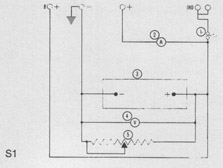

Fig. S.1. illustrates

a Test Circuit for 15ACR and

17ACR alternators with standard terminations, battery-

sensed.

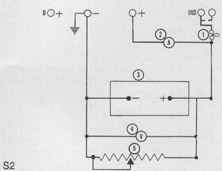

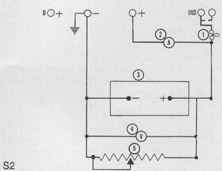

Fig. S.2. illustrates a Test Circuit for 15ACR and 17ACR

alternators with standard terminals and two piece con-

nection plug (machine-sensed).

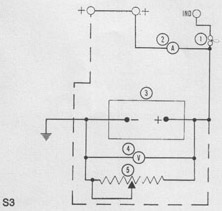

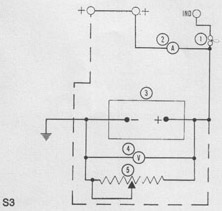

Fig. S.3 illustrates a Test Circuit for 15ACR, 17ACR, 18ACR,

23ACR, A115/45. A127. A133/55 and LR series alternators

with European terminations and single 3 terminal connector

plug (machine-sensed). Broken line cable connection applies

to battery-sensed, in which case, the connections between

the two • + ' terminals will not apply and the broken line ter-

minal will be marked "S" instead of ' + '.

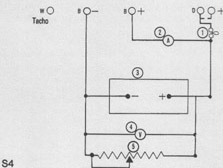

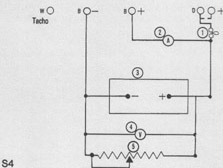

S.4 shows a test circuit for Motorola 9AR.

Value of components in Figs. S.1, S.2, S.3 and S.4 are as

follows:-

1. 12 volt 2.2 watt bulb.

2. 0 - 60 ammeter

3. 12 volt battery

4. 0 - 20 moving coil voltmeter.

5. C - 1 5 o^t 50 amp variable resistor.

Alternator Output Test with Regulator Inoperative

Withd-aw the cable connector(s) from the alternator.

remo'.e the moulded cover (secured by two screws)

and earth the regulator green lead or connector strip

tc 'rare.

Connect an external test circuit to the alternator output

terminals as shown in Figs. S.1, S.2, S.3 or S.4.

Observe carefully the polarity of battery and alternator

terminals - reversed connections will damage the

alternator diodes.

The variab!e resistor across the battery terminals must

not be left connected for longer than is necessary to

carry out the following test.

Start the engine. At 1,500 rev/min (alternator speed).

the test circuit bulb should be extinguished. Increase

engine speed until the alternator is running at 6,000

rev/m;n approximately, and adjust the variable resist-

ance until the voltmeter reads 13.6 volts. The ammeter

reading should then be approximately equal to the

rated output (see previous heading). Any appreciable

deviation from this figure will necessitate the alternator

being removed from the engine for further examination.

Failure of one or more of the diodes will be indicated

in the above test by effect on alternator output, and

also in some instances by abnormally high alternator

temperature and noise level.

Regulator Test

The following test assumes the alternator to have been

tested and found satisfactory.

Disconnect the variable resistor and remove the earth

connection from the regulator green lead or connector

strip to frame.

With the remainder of the test circuit connected as for

the alternator output test, start the engine and again

run the alternator up to 6,000 rev/min until the ammeter

shows an output current of less than 10 amperes. The

voltmeter should then give a reading of 13.6 - 14.4

volts. Any appreciable deviation from this (regulating)

voltage means that the regulator is not functioning properly

and must be replaced.

If the foregoing tests show the alternator and regulator

to be satisfactorily performing, disconnect the test

circuit and reconnect the alternator terminal connector.

Now connect a low range voltmeter between the posi-

tive terminal of the alternator (the moulded terminal

connector is open ended to facilitate this) and the

positive terminal of the battery. Switch on battery load

(headlights etc.), start the engine and increase speed

until the alternator runs at approximately 6,000 rev/min.

Note the voltmeter reading.

Transfer the voltmeter connections to the negative

terminals of the alternator and battery and again note

the meter reading.

If the reading exceeds 0.5 volt on the positive side or

0.25 volt on the negative side, there is a high resistance

in the charging circuit which must be traced and remedied.

© Dodge50.co.uk™ 2002