With a large diagram at bottom of page

2. The lamps do not dim, the voltmeter

reading

remains steady at about 12 volts, and the motor

does not crank the engine.

Connect voltmeter from solenoid terminal 'BAT',

and starter yoke, operate starter:-

No volts indicated.

a) Poor lug connections at battery.

b) Bad earth connection.

c) Broken starter lead, battery to starter.

Full volts i.e., 12-14 volts indicated.

a) Faulty solenoid switch.

b) Open circuit in starter - check brushes.

Starter Motor

Model • CA45

General Description

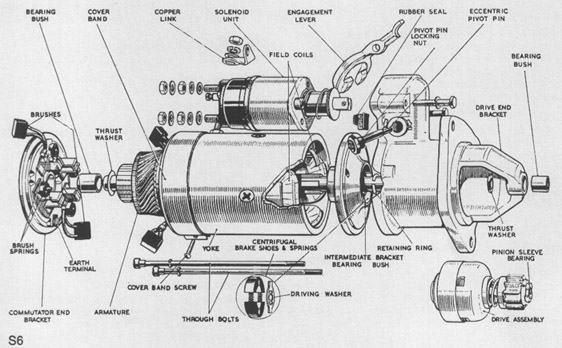

Designed for flange mounting, the C.A.45 starter motor

has a uniform cylindrical shape with no surface pro-

trusion. This is because the solenoid and main switch

assemblies are housed within the drive end-shield,

around (i.e.. co-axially with) the armature shaft.

The essential feature of the co-axial starter is that,

the pinion alone moves axially to engage the engine

flywheel. There is no longitudinal movement of the

whole armature assembly, as in the axial types.

Smooth engagement of the pinion with the engine fly-

wheel is constantly ensured by using two-stage opera-

tion of the solenoid and switch mechanisms. Thus the

risk of damage to both pinion and flywheel, through

faulty meshing, is practically eliminated.

In construction, the starter consists of three main

sections, into which it can be easily dismantled.

1. The solenoid switch-gear and pinion assembly

housed in the drive end-shield.

2. The armature, shaft and commutator assembly.

3. The yoke, pole-piece and field-coil assembly.

Ready access is possible therefore, to those parts most

likely to require adjustment, such as the switchgear

and commutator assemblies.

The starter is designed for working off a 12 volt supply,

with 17 amps solenoid current.

Testing on the Vehicle

Ensure thai the battery is in a charged condition.

Switch on 'he lamps and operate the starter button. If

the starter fails to function, but the lights maintain full

brilliance, check the switch and battery connections to

the starter and all external leads. Sluggish action of the

starter can be caused by a poor or faulty connection.

Difficulty in smooth engagement between starter and

engine flywheel is probably due to dirt on the starter-

shaft helices preventing free pinion movement. The

shaft should be thoroughly cleaned with kerosene

followed by the application of a small quantity of Caltex

Thuben 90 or SAE 90 oil.

Operating the Starter

When starting the engine the following points

should be rigidly observed

1. Press the starter button firmly and release it

Immediately the engine fires.

2. If the engine does not fire at once, let it come to

rest before pressing the switch again.

3. Do not run the battery down by keeping the starter

switch pressed when the engine refuses to start.

Ascertain the cause.

4. On some engines it is often helpful to depress the

clutch when starting.

5. Do not operate the starter when the engine is run-

ning as serious damage may occur to both starter

and flywheel.

© Dodge50.co.uk™ 2002