Welcome to another splendid and helpful page from ©dodge50.co.uk

|

|

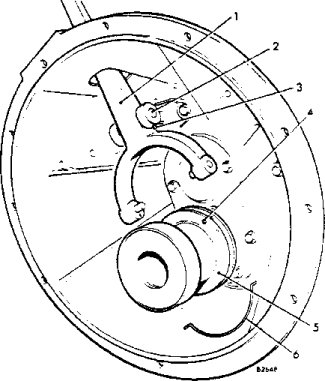

Clutch Unit and Withdrawal Mechanism Section

E040 To

Dismantle

Examine the withdrawl fork for damage particularly in the region of the flucrum pivot. Check the fit of the fulcrum pin and fork bush. Renew both if worn. Check the bearing assembly for wear or damage. To

Re-assemble Note:

The anti-rotation pin must be fitted away from the bearing assembly

retaining ring. Refitting is a reversal of the removal procedure noting the following. Lightly smear the withdrawal lever fork and gearbox primary shaft spline with white Kleenomax L2 grease. Fit a new split pin through pivot block and pivot Din.

1. WITHDRAWAL FORK 2. FORK PIVOT PIN 3. SPLIT PIN 4 ANTI-ROTATION PIN 5. BEARING ASSEMBLY 6. BEARING ASSEMBLY RETAINING RING

|

|

PartsContacts Pictures Service Pages For Sale Dodge History Wiring Diagram Expensive Dodge Ramblings |

© Dodge50.co.uk™ 2002

Dodge

50 Series Workshop Manual

Dodge

50 Series Workshop Manual