HYDRAULIC SYSTEM All Dodge 50 Series Vehicles

The hydraulic system operates with two independent circuits, one supplying the front and the other the rear brakes. If a leak develops in one circuit the other is unaffected. Regularly check the hydraulic system for leaks, damage, chafing or corrosion. Have any defects rectified immediately.

Checking Fluid Level

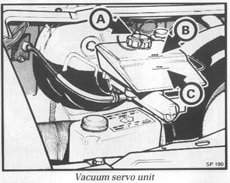

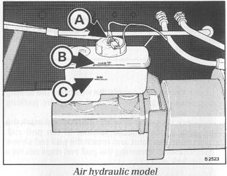

The brake fluid reservoir is located

beneath the bonnet on vacuum hydraulic models or behind the cab, on the outside

of the chassis sidemember on air hydraulic models. The translucent container

allows the level to be seen without removing the cap.

Correct fluid level (B) is indicated on the front face of the reservoir marked

'MAX'. Do not overfill.

Never allow the fluid level to fall to the 'MIN' mark (C).

Fluid levels should be checked physically at regular intervals. Frequent necessity

for topping up indicates a fluid leak which must be rectified immediately.

If topping up is necessary, clean the area surrounding the cap thoroughly before

removal. Top up with clean unused fluid to the correct specification, replace

the cap.

To check operation of warning system

To check the low level warning light

bulb simply open the cab door. The warning light should illuminate.

To check the operation of the low level warning switch (A) mounted in the cap

of the fluid reservoir, proceed as follows:-

1) Ensure that the cab interior lamps are switched to the courtesy position

i.e. lamps only light when doors are open.

2) Close both cab doors.

3) Press the filler cap and check that cab interior lamps illuminate.

Bleeding the system

This is not a routine maintenance item and should only be necessary when air has entered the system. Entrust this work to your authorised dealer if required. Click Here for my personal help. ( Will put up detailed instructions when I get Time )

Hydraulic pipe connections

Check for leaks and damage of pipe lines, unions, flexible hoses, etc. If tightening

of unions is necessary over tightening must be avoided - THIS WORK SHOULD BE

ENTRUSTED TO AN AUTHORISED DEALER

Due to the use of salt to disperse snow and ice on roads during winter months,

it is important that brake pipes are checked (without dismantling) for corrosion

at the recommended intervals.

Changing Brake Fluid, Seals

and Hoses

In the interest of safety it is recommended that hydraulic fluid, seals and

flexible hoses are renewed at the intervals stated in the Service Schedule.

LOAD SENSING VALVE

The load sensing valve regulates the braking pressure passing to the rear brakes so that maximum pressure is only available when the vehicle is fully laden. As the vehicle's load is reduced the valve automatically lowers the braking pressure.

Accurate setting of the valve is essential and should be carried out by your

dealer. A brake data plate is located on the vertical panel of the step well

showing the valve setting dimension 'Y' for your vehicle. The 'Y' dimension

is determined using the unladen weight of the rear axle and is set before delivery

to the operator. Any alteration which may change the unladen weight e.g. change

of body will necessitate re-setting the valve. A change of rear springs will

also require valve re-adjustment. A new brake data plate will have to be fitted

showing the new unladen weight and 'Y' dimension.

During the normal life of the vehicle the valve will require re-adjustment due

to spring settlement (especially during its early life) at the periods shown

in the service schedules.

© Dodge50.co.uk™ 2002