Dodge

50 Series Workshop Manual Dodge

50 Series Workshop Manual

A440

Page's 6 & 7

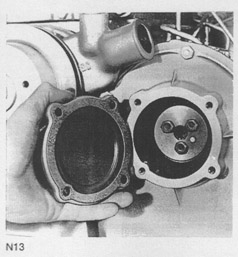

3. Remove

the timing case front cover inspection

plate (Fig. N.13).

4. Remove the three setscrews or nut which secure

the fuel pump gear to the fuel pump.

5. Remove the fuel pump from the timing case ensur-

ing that when the fuel pump gear leaves the shaft

it stays in mesh with the idler gear otherwise the

fuel pump timing will be affected

To Refit the Fuel Pump

(Mechanical Governor)

1. Replace the fuel pump ensuring that the slot, or key

in the pump hub, or shaft is aligned with the dowel

(or keyway) in the gear.

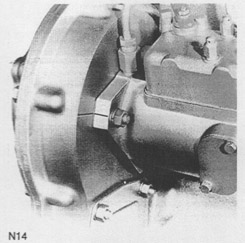

2. Position the pump so that the scribed line on the

pump flange aligns with the mark on the timing

case (Fig. N.14). Secure the pump to the timing

case. To check accuracy of mark on rear of

timing case. this may be ascertained in accordance

with the instructions for marking a new timing case.

3. Secure

the driving gear to the fuel pump shaft with

tne tn'ee setscrews and spring washers, or nut

ensuring the dowel or keyway is properly located in

us slot.

4. Fit the timing case inspection cover.

5. Refit the low and high pressure pipes to the fuel

pump,

6. Re-connect the throttle and stop lever controls and

attach the return springs.

7. Vent the air from the fuel system .

8. Adjust the maximum and idling speeds,

NOTE; Where a fuel pump rear support bracket is fitted,

ensure that when the fasteners are tightened the pump

or bracket are not stressed.

Fuel Pump Gear

To Re-set the Fuel Pump Timing - D.P.A.

On the fuel pump rotor, inside the fuel pump are a

number of scribed lines, each one bearing an indi-

vidual letter. A timing circlip is positioned inside the N14

pump and has to be set so that when the appropriate

scribed line on the fuel pump rotor aligns with the

scribed line on the circlip, it denotes

commencement of injection (static timing).

NOTE: On later engines

the scribed line on the circlip

has been deleted. On these engines the scribed line on

the rotor should be aligned with the end of the circlip

which has the straight edge. The circlip on

current pumps is not set and timing tool MS67B must

be used.

To set the

timing circlip, it is necessary to remove the

pump from the engine and fix the position of the circlip

by connecting No. 1 cylinder outlet connection (marked

"W") to an atomiser tester and pump up to 30 atm

(31 kgf/cm' or 440 Ibf/in2).

Turn the

pump by hand in

the normal direction of rotation until it "locks up".

The squared end of the circlip should now be adjusted

until it lines up with the letter "A" for hydraulic pumps

or the letter "C" for mechanical pumps, on the pump rotor.

To re-set the fuel timing the following procedure 5.

should be adopted:-

a)

Hydraulically Governed Pump

Ensure that the fuel pump circlip is correctly positioned

as described previously.

1. Ensure that the fuel pump is correctly fitted with

the scribed line on the mounting flange aligning

with the mark on the fuel pump gear carrier (Fig.

N.12).

2. Position the crankshaft so that No. 1 piston is at

T.D.C. on compression stroke.

3. Remove the collets, spring cap and spring from the

inlet valve of No. 1 cylinder and allow the valve to

rest on the top of the piston.

4. With the aid of a clock gauge in contact with the

end of the valve now resting on the No. 1 piston

it will be necessary to position the crankshaft at

the static timing position.

5. Remove the inspection plate on the fuel pump en-

abling the rotor to be seen.

|

Dodge

50 Series Workshop Manual

Dodge

50 Series Workshop Manual