Dodge

50 Series Workshop Manual Dodge

50 Series Workshop Manual

A440

Page's 7 & 8

6. With

No. 1 piston at the static timing point on its

compression stroke, the scribed line on the fuel

pump rotor marked "A" should align with the

scribed line or straight edge on the circlip.

If it does

not, release the fuel

pump drive plate securing setscrews and turn the

drive plate on the slotted holes, the required

amount to bring them into alignment. Access to

the drive plate is gained by removing the timing

case front cover inspection plate

7. When the fuel pump timing is correct, obliterate

the mark on the fuel pump drive gear and re-mark

the gear to correspond with the mark on the fuel

pump drive plate

8. Refit the spring, spring cap and collets to No. 1

inlet valve and refit the pump inspection plate and

timing case inspection plate.Re-seal

the inspection plate.

(b) Mechanically Governed Pumps- D.P.A.

The procedure for re-setting the fuel pump timing on

mechanically governed engines is similar to that used

for hydraulically governed engines with the exception

of the method of pump adjustment.

As there is no adjustable fuel pump drive plate on a

mechanically governed engine, the adjustment is carried

out by slackening the nuts on the pump mounting flange

and rotating the pump body until the scribed line on the

rotor, marked with the letter 'C' aligns with the scribed

line or straight edge of the circlip.

The circlip on current pumps is not set and timing tool

MS67B must be used.

To Check Marking Angle of Fuel Injection

Pump using Tool MS.67B

- D.P.A./D.P.S. Pumps

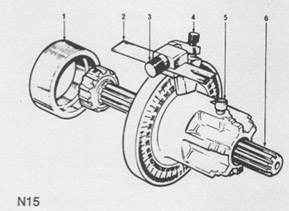

1. Release screw (5, Fig. N.15) and remove splined

shaft (6). If pump has a slotted hub, the splined

shaft should be retained with the small -r ihed

diameter to the rear to locate in the centre of the

hub.

2. Ensure that slotted pointer (2) is positioned with

slot to rear of tool and chamfered sides of slot

outwards. At this stage, slotted end of pointer

should be kept well back towards body of tool.

Ensure that the flat in the washer fitted behind the

pointer securing screw (3) is located over side of

pointer.

3. Release bracket screw (4) and set bracket so that

the chamfered edge is in line with the relevant

marking angle.

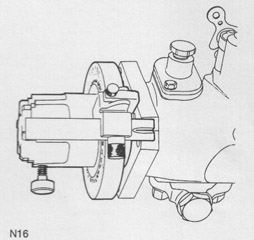

4. Position timing tool on pump drive shaft with master

splines engaged and tool locating on spigot (see

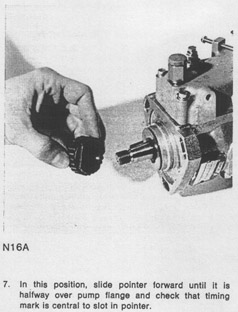

Fig. N.16). For D.P.S. pumps, first fit adaptor PD67-3

to end of pump drive shaft, (see Fig. N.16A). With

dowel drive pumps, locate splined shaft in hub, slide

tool towards pump to rest on end of hub and lock

shaft in tool (See Fig. N17).

5. Connect No. 1 outlet of pump body to an atomiser

test rig and pump up to 30 atmospheres (31

kgf/cm-') -440 Ibf/in2. If pressurising valve is

fitted this must be removed.

6. Turn pump in normal direction of rotation as shown

on pump nameplate, until it locks.

N16A

7. In this position, slide pointer forward until it is

halfway over pump flange and check that timing

mark is central to slot in pointer.

|

Dodge

50 Series Workshop Manual

Dodge

50 Series Workshop Manual