Dodge

50 Series Workshop Manual Dodge

50 Series Workshop Manual

A440

Page's 8 & 9

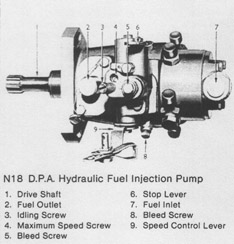

When fitting

a replacement fuel pump, or in the event of

the maximum

speed screw having been moved, the max-

imum no load speed must be checked and re-set as

necessary.

The maximum no load speed will vary according to

application. For details, reference should be made to

the code number stamped on the fuel pump data plate.

The last four numbers in the code indicate the speed

required, and in the case of the example on page N10,

this would be 3130 rev/min.

To Check Marking Angle of Fuel Injection Pump

using Tool MS. 67B and adaptors PD.67B-1 and

PD. 678-6 (Stanadyne Pump)

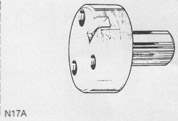

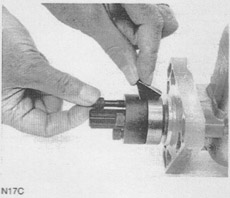

1. Fit the adaptor PD.67B-1 (Fig. N17A) to the hub of

the pJms by use of the special setscrews, part of

tool PD.67B-6 (Fig. N17C). Ensure that the location

slots of the hub and adaptor are together and in line

(use the alignment gauge, part of tool PD.67-6) and

that the adaptor is concentric with the hub.

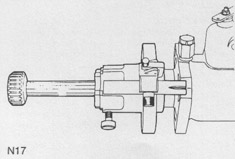

2. Remove the splined shaft from the timing tool

MS.67B (6. Fig. N15) and slide the small splined

open end of the timing tool onto the splined shaft of

adaptor PD.67B-1 (Fig, N17D). Lock the timing tool

into position with the securing screw (5, Fig. N15).

3. Ensure the long pointer, part of tool PD.67B-6 is in

position and that the sides of the slot with chamfers

are on the outside. Ensure that the flat of the

washer fitted behind the screw (3, Fig. N15) which

fastens the pointer is in position.

4. Release the screw (4, Fig. N15) which fastens the

bracket and set the bracket so that the edge with a

chamfer is in line with the correct fuel injection

pump mark angle.

Note: As the tool will have to be fitted in the reverse

position to normal; the setting angle has been

adjusted to allow for this.

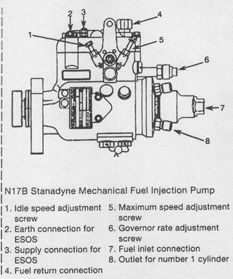

5. Connect No. 1 cylinder outlet (8, Fig. N17B) to an

atomiser tester and operate the tester until it

reaches 31 kgf/cm2 (30 atm or 440 Ibf/in2). If a

pressure vaive is fitted, this must be removed.

6. Turn the drive shaft of the pump backwards and

forwards until the fuel pressure prevents movement

of the shaft. This is necessary as fuel must pass the

delivery valve in the fuel pump before the fuel

pressure will prevent movement of the shaft. In this

position, the fuel pump is set at the start of ignition

from number 1 outlet.

7. Move the pointer forward until it is half over the

pump flange. Check that the timing mark is central

to the slot in the pointer. Make a new timing mark if

necessary.

©

Dodge50.co.uk™

2002 |

Dodge

50 Series Workshop Manual

Dodge

50 Series Workshop Manual